Introduction

We've developed a bit of a sub-specialization in thermal energy plants with the completion of UTMB's East Plant. This is number three for Work5hop's personnel (UTSA's North Thermal Energy Plant and Northeast Lakeview College's Physical Plant are the others, both done while with another firm). A fourth plant -- a substantial expansion of UTMB's West Plant -- is under construction now.

A thermal energy plant is an unusual building, and designing one requires attention to a different set of considerations than most projects. In particular, thermal energy plants on hospital campuses are hugely important. They are the key to the critical buildings on campus remaining open and functional. At UTMB, that includes hospitals and research facilities. This critical care capacity means that the campus cannot simply shut down.

Design

The architectural design brief for the East Plant, then was twofold: first, it had to be a hardened facility capable of resisting hurricane-force winds while continuing to deliver utilities to the campus. Second, it needed to be, visually, a good partner to the rest of the campus. Most buildings have the advantage of appropriately-scaled floors, large areas of glazing, or even just the occasional window to help out with massing and scale. Not here -- the plant has very tall floors and glass was ruled out due to the expense of storm-resistant glazing. The East Plant must blend into the character of campus without those architectural tools, and it should aesthetically step back, allowing feature buildings (like the new hospital and future new research buildings) to catch your eye.

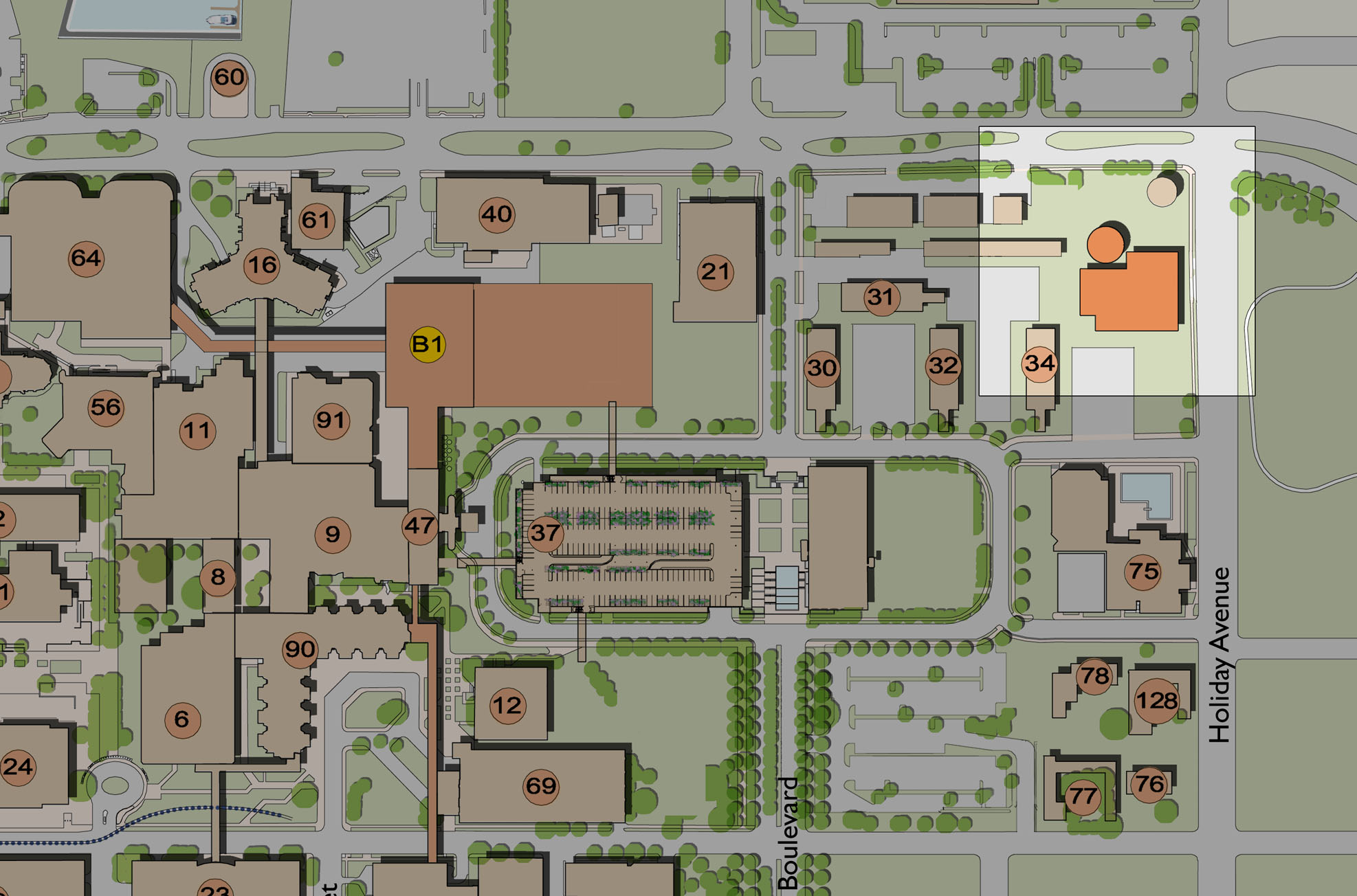

Below: campus plan, showing the East Plant site highlighted in the top right corner

Below: campus plan, showing the East Plant site highlighted in the top right corner

Cladding and Massing

Exterior cladding is a blend of materials used extensively elsewhere on campus, including brick, precast concrete, and sitecast concrete. The precast panels are intentionally overscaled in order to reduce the apparent size of the building. Our minds assign a size to a building based on visual cues like the height of stories and the size of elements on the building. The very tall stories (because of the huge mechanical equipment inside) and large panels of precast concrete help to convince the mind that the building is smaller than it actually is.

It's also a visually compact building. The roof-mounted cooling towers were brought into the mass of the building with large, primarily open screens. These screens form a frame around the towers, which would otherwise look like pieces of equipment plunked onto the roof. Materials are also used to articulate the building: the stair towers are clad in brick, visually anchoring the rest of the mass. Brick is also used at grade all around the building because it is a softer, more human-scaled material than the precast concrete.

Below: Precast concrete being produced for the East Plant

Below: Precast concrete being produced for the East Plant

Mechanical

Honestly, though, the building really isn't about its architecture. It's about the mechanical equipment inside it, including 7,100 tons of cooling capacity (for reference, the air conditioner at your house is probably 3 to 5 tons), a 7.5 kW combined heat and power turbine (i.e., a small jet engine IN THE BUILDING), and nearly 3,000 horsepower in the water pumps alone. It's pretty cool stuff. That turbine means that the building generates electricity and can power critical facilities on campus even when the island's power goes down. Also, the cooling capacity can be doubled as the campus grows.

Below: Cutaway view of the East Plant

Below: Cutaway view of the East Plant

Conclusion

We tackle lots of different kinds of projects at Work5hop, from a behemoth like the East Plant, to delicate residential restorations, diverse commercial and public projects, and long-term master planning. We have particular strengths in problem solving and working collaboratively to come up with unique solutions. If that sounds appealing to you, we hope you'll contact us for your next project.